Perforated mesh: is there a cheaper alternative?

Perforated mesh: is there a cheaper alternative?

With raw material costs rising, it may be time to consider making a switch from perforated mesh to expanded metal mesh.

Why?

To manufacture perforated metal panels, several techniques are used.

‘Cold perforation’ entails using a roller full of pins, which is run over a metal sheet to punch the holes out. In ‘hot perforation’, heated pins are used instead.

There is also the die and punch process: a sheet with protruding needles is pressed on to a metal sheet as it rolls through a punch press.

In addition, laser perforation can be used, with holes burned into the metal sheet.

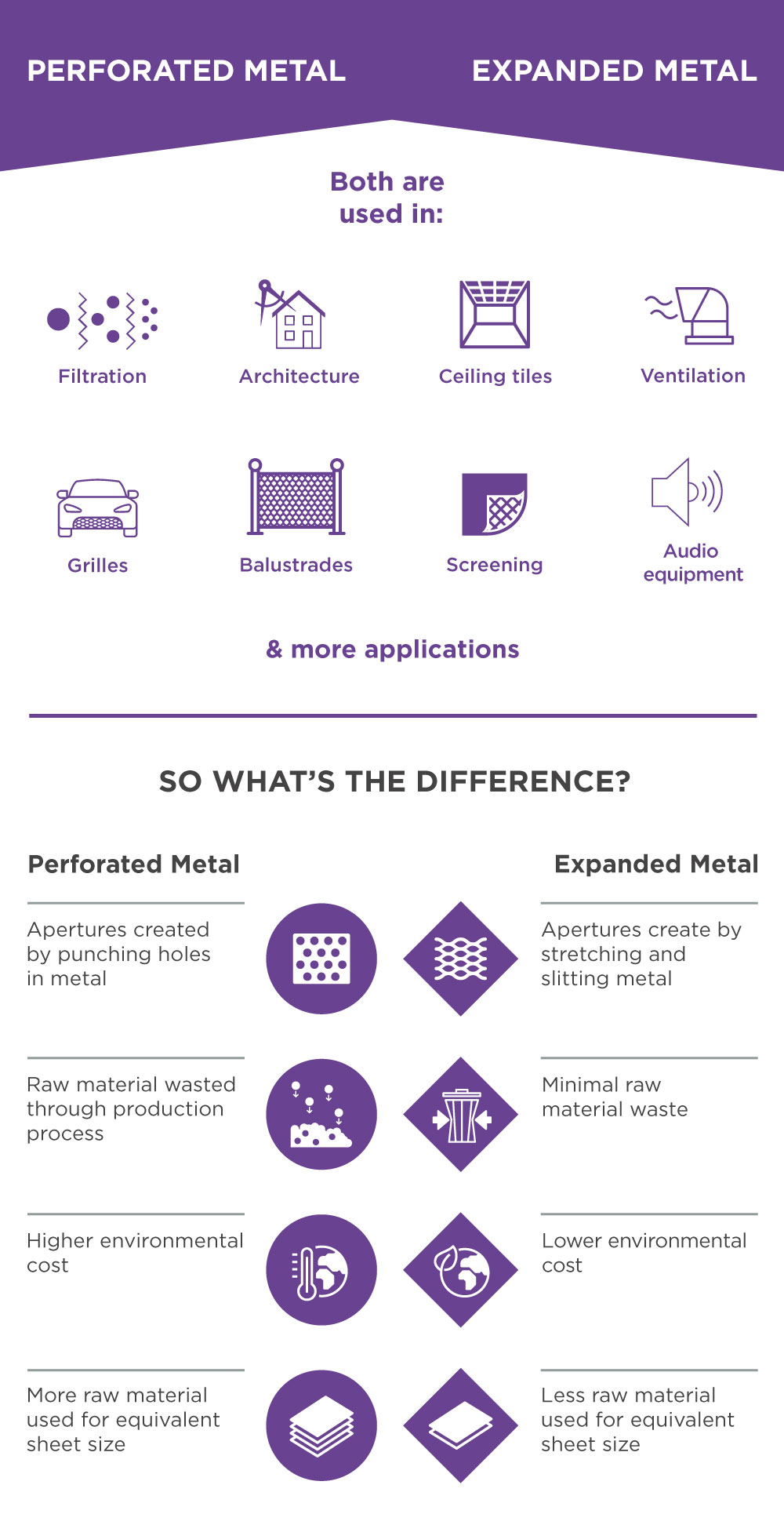

However, in all of these cases, raw material is wasted when the holes are punched or burned out.

Save money by switching from perforated metal panels to expanded metal

Up to 50 per cent of raw material costs could be saved by using an expanded metal sheet rather than its perforated mesh equivalent

This is because expanded metal is formed by slitting and stretching sheets, rather than punching through holes.

The result? Minimal waste of raw material.

When applied to a material such as stainless steel or galvanised steel, end users could make significant savings when switching from perforated metal panels to expanded metal.

Comparing perforated metal panels to expanded metal

Here’s how a switch from perforated mesh to expanded metal can make a real difference…

To manufacture a 1250mm x 2500mm R3T5 perforated metal sheet, 17.15kg of steel plate would be required.

But to manufacture an equivalent 1250mm x 2500mm N6664F Experf sheet, just 7.5kg of steel plate would be needed.

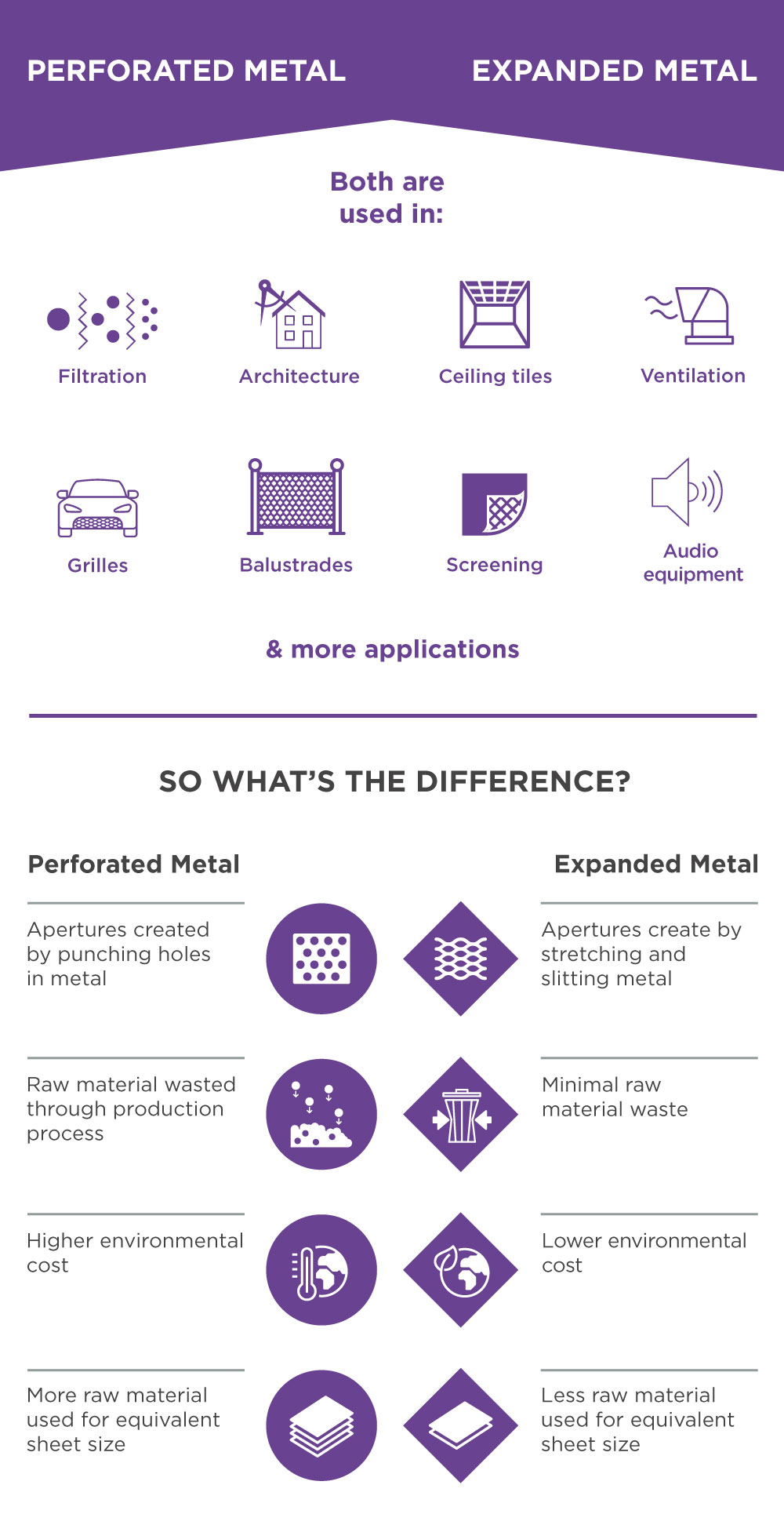

Expanded metal can be used in many of the same applications as perforated metal including filtration, architecture, shopfitting, ventilation, grilles, balustrading, audio and screening.

Contact us to make the switch

For more information on making the switch from perforated mesh to expanded metal, contact our team today!