How to measure and specify expanded metal

Download our mesh measuring guide.

Understanding the precise measurements required for different types of expanded metal is essential for selecting the right mesh pattern. In this article, we provide a comprehensive guide on how to accurately measure and specify expanded metal.

Raised or flattened mesh, what is the difference?

When measuring expanded metal mesh, the first thing to consider is whether the mesh is raised or flattened. Each type has its own set of terminologies for measurement.

Expanded metal starts in a raised form due to the unique ‘slit and stretch’ manufacturing process, which creates angular strands inclined from the plane of the sheet.

Raised mesh is notable for its angular appearance, which not only enhances its aesthetic appeal but also provides practical benefits: it offers grip underfoot, directs air, liquid, and light, and serves as a key when used as a substrate.

Common applications for raised mesh include walkway ramps, security fencing, interior and exterior decorative building cladding, and laths for render and plaster.

A secondary process often flattens the raised mesh using heavy rolls, resulting in a completely two-dimensional sheet where all strands lie in the same plane. Flattened mesh is preferred when a smooth finish is desired.

Common applications for flattened mesh include security partition meshes, conical air filters, and machine guards.

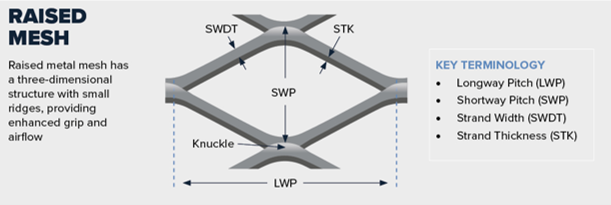

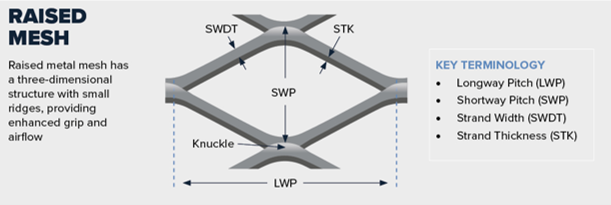

How to Measure a Raised Mesh?

Key terminology for raised mesh is Longway Pitch (LWP), Shortway Pitch (SWP), Strand Width (SWDT) and Strand Thickness (STK).

LWP: Measured horizontally from either knuckle to knuckle or centre to centre, is derived from the size of tooling used within the production process.

SWP: Measured vertically from either knuckle to knuckle or centre to centre, is manifested through the overall expansion applied during manufacture.

SWDT: A measurement of the width of the resulting angular strand created during manufacture.

STK: A measurement of starting raw material thickness. Contrary to belief, the expanding process does not directly alter material thickness. Strand Thickness should not be confused with the overall height or depth of expanded metal. Typically, mesh height can be as much as 1-2 times the measurement of SWDT.

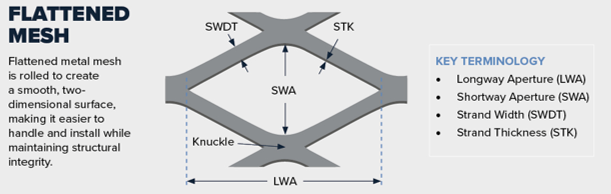

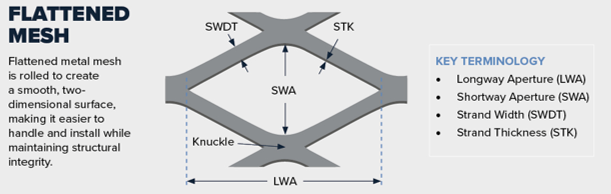

How to Measure a Flattened Mesh

Key terminology for flattened mesh is Longway Aperture (LWA), Shortway Aperture (SWA), Strand Width (SWDT) and Strand Thickness (STK).

LWA: Measured horizontally from one internal aperture point to the next.

SWA: Measured vertically from one internal aperture point to the next.

SWDT: The width of the angular strand created during manufacturing.

STK: The thickness of the raw material before processing.

The expanding process does not alter the material thickness, but the flattening process does. You can expect a 10-20% reduction in material thickness after flattening.

After flattening, the mesh becomes completely two-dimensional. Therefore, the overall height measurement of the mesh will be similar to the starting material thickness, with an additional 10-20% reduction.

How do I specify sheet size and orientation?

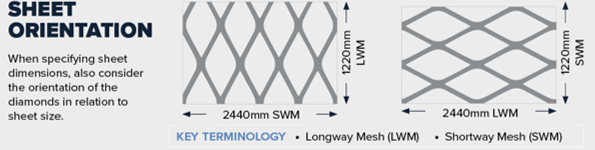

Expanded metal mesh exhibits different mechanical and aesthetic properties depending on the sheet's orientation.

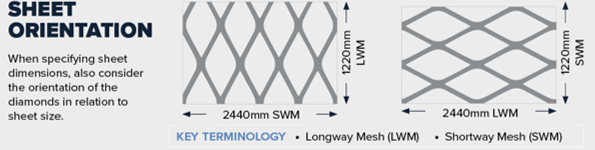

When specifying sheet dimensions, it is important to consider the orientation of the diamonds in relation to the sheet size. The terms used to describe this orientation are Longway Mesh (LWM) and Shortway Mesh (SWM).

For example, when raised mesh is used as a walkway ramp platform, the surface grip is strongest when the diamonds run left-to-right underfoot. Conversely, in the security fencing industry, expanded metal fencing panels are commonly mounted with the diamonds pointing upwards. This creates narrower openings and makes it more difficult to climb and scale the fence.

The illustration below shows how a 2440mm (LWM) x 1220mm (SWM) differs from a 1220mm (LWM) x 2440mm (SWM), despite having the same overall dimensions.

In conclusion, this article has provided a comprehensive guide on measuring and specifying expanded metal, covering both raised and flattened mesh types. It delves into the unique characteristics and applications of each, highlighting key measurements.

These measurements are essential for selecting the right mesh pattern for various purposes, from walkway ramps and security fencing to decorative cladding and industrial applications.

By understanding these metrics and considering the orientation of the mesh, readers can confidently choose expanded metal that best suits their specific needs. For visual clarity, refer to the accompanying illustration to understand the differences in mesh orientation.

View an example of our 2076F flattened steel mesh at a horizontal orientation here and view the same mesh at a vertical orientation here. You can also view our 2089 raised steel mesh at a horizontal orientation here and at a vertical orientation here.

For more support and to discuss your requirements further, contact us.